Now we have a lot to talk about today.

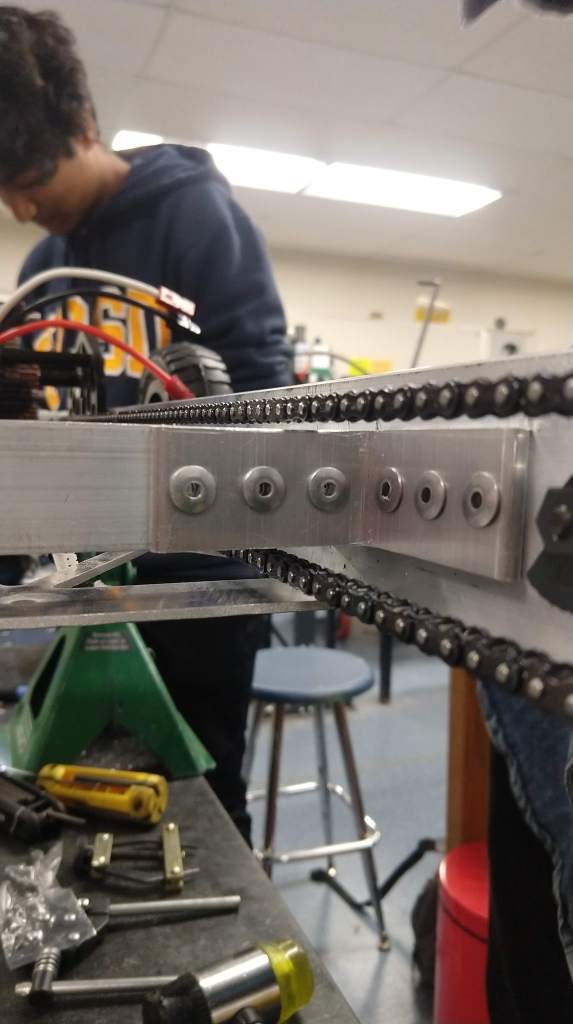

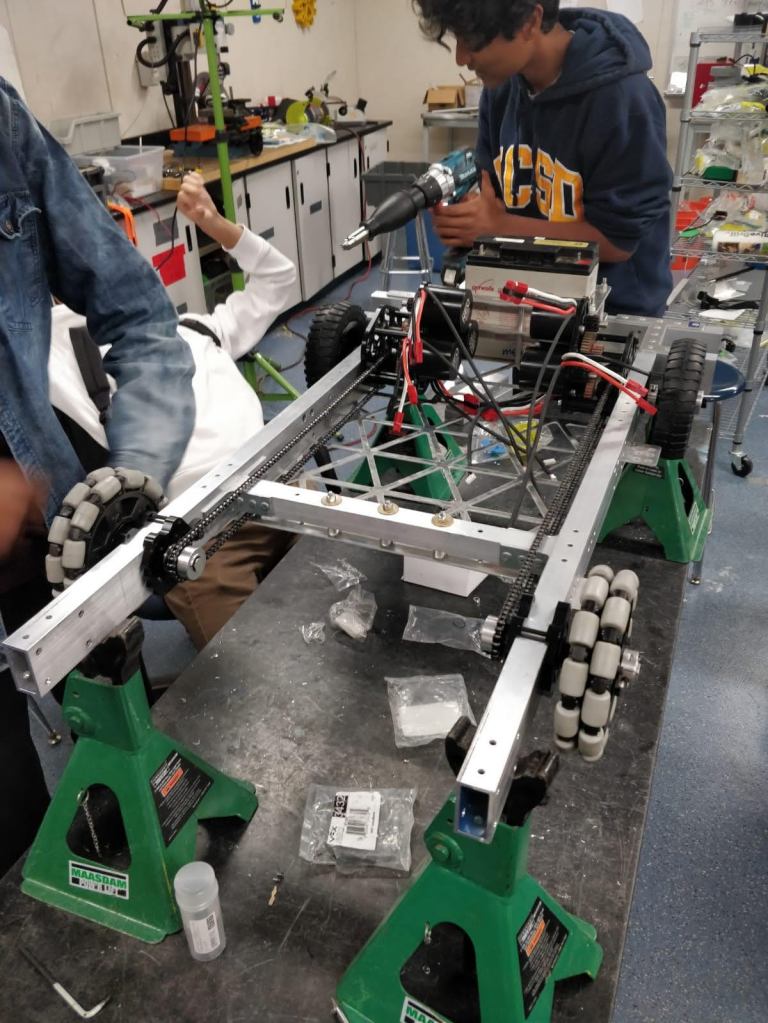

The drivetrain was completed on Monday (February 3rd) and it worked out flawlessly. We easily got it assembled with the brackets on top and drilled out holes on the bottom of the baseplate to use for rivet attachment. The gearboxes, chain, and wheels work together as planned and it all fits together perfectly. A couple of small things need to be added, but the drivetrain is basically complete.

Yesterday and today we kept working on more parts for the robot. We’ve been spending some time over the past couple of weeks working with the CNC and figuring out its intricacies so that we can use it more for the robot. We still haven’t mastered it and continue to encounter some problems, but we were able to figure out some things that work today and get our first piece done. The first complete pieces technically came out very wrong and as a result of a problem with the cutting, but we were nevertheless able to clean it up and get it ready for the robot. We will continue working on getting the CNC ready for more parts and, when we get it working, we’ll be able to have some quick turn-around time on some parts.

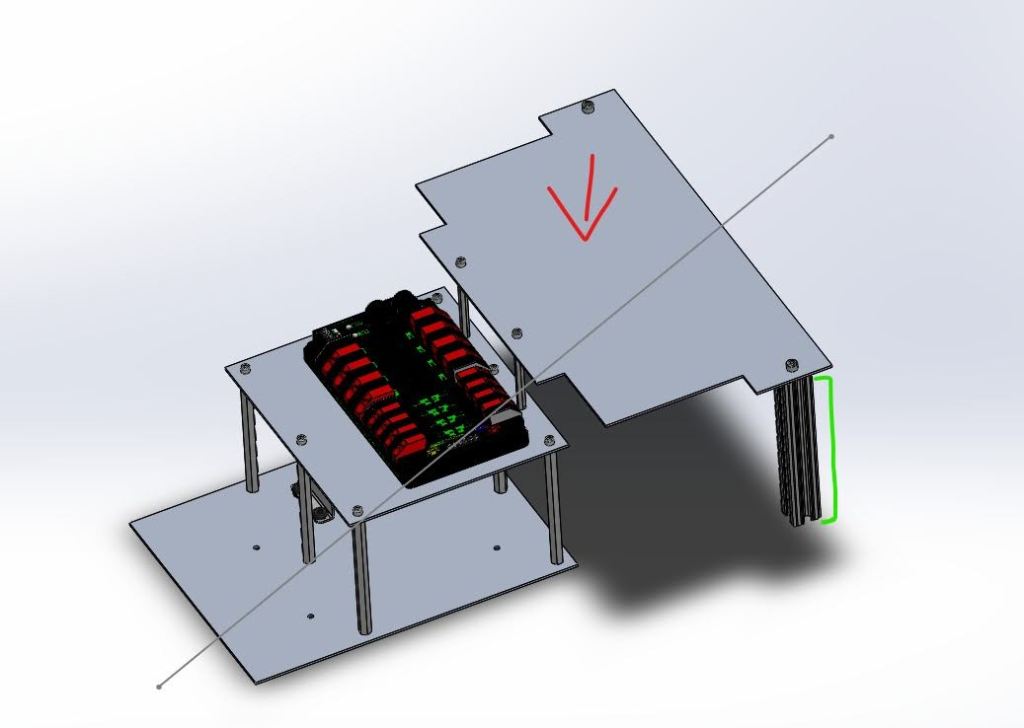

Build has also started working on the electrical plate today. That was finished before the meeting and electrical has started working on adding components. We should be finished with that soon enough so that we can wire the drivetrain at the very minimum (and let software start testing).

As we look forward, we’ve slightly modified our plan. Because of the complexity of the robot and the sheer amount of parts we have to make, we won’t be able to finish the entire robot by Sunday. However, we still hope to be able to wire and assemble the tube and intake sub-assemblies onto the robot by the end of the weekend. That way, software should still be able to begin testing the shooting alignment and autonomous at the beginning of next week. At the same time, we will be able to assemble the whole elevator off the robot and attach it to the robot in less than 30 minutes.

To meet the deadline of Saturday for the tube and intake, we need only complete two side beams (one of which is halfway done) and get some waterjet plates. We will be working eight hours on Saturday so it definitely seems achievable. At the same time we hope to be able to use the initial versions of those sub-systems (which will be made out of lexan instead of metal) to test some uncertain parameters (like ball compression and intake extension) and modify quickly if needed. More blog posts to come (and hopefully pictures of more full assemblies) within the next couple of days.