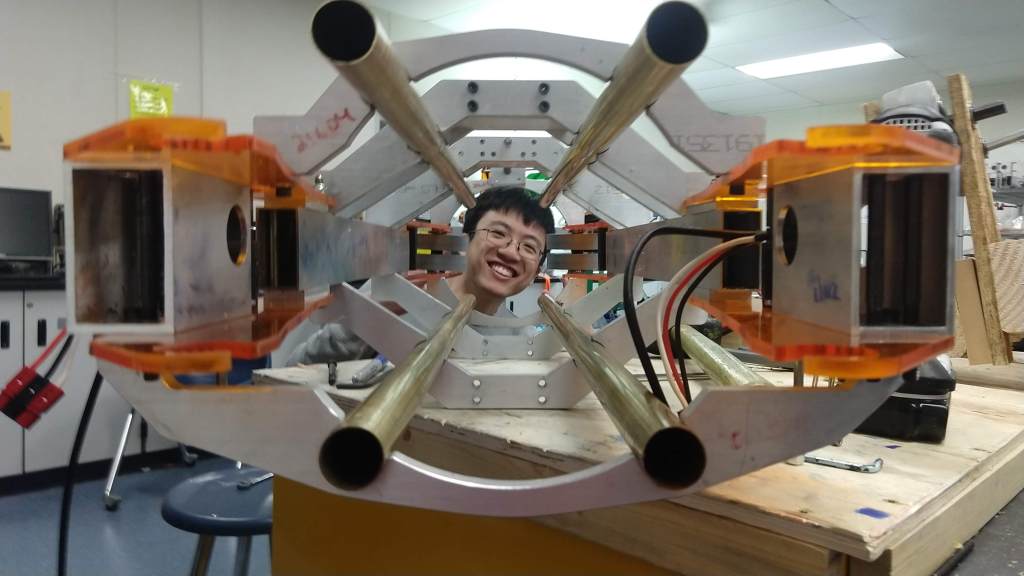

Over the past couple of days we’ve continued working on finishing up climber pieces as well as completing, testing, and attaching the tube and intake onto the chassis. We were able to get the shooter and intake plates for the tube attached on Tuesday and some of the wheels and motors that go along with that as well. We also worked on welding the polycord together and attaching it along the length of the tube (a process that required a good amount of force). All in all, the tube was finished before 6pm yesterday.

At the general meeting yesterday we were also able to use the completed intake to Frankenstein it to the electrical system. We wanted to test out whether the compression on the balls was right for shooting them out. It turns out that Gary’s eyeballing seemed spot on. The balls shoot out fine and it doesn’t seem like adjustment will be necessary. In addition we tested the belt system using some drills and, if both sides are powered at the same speed (which they will be with motors), it will work perfectly.

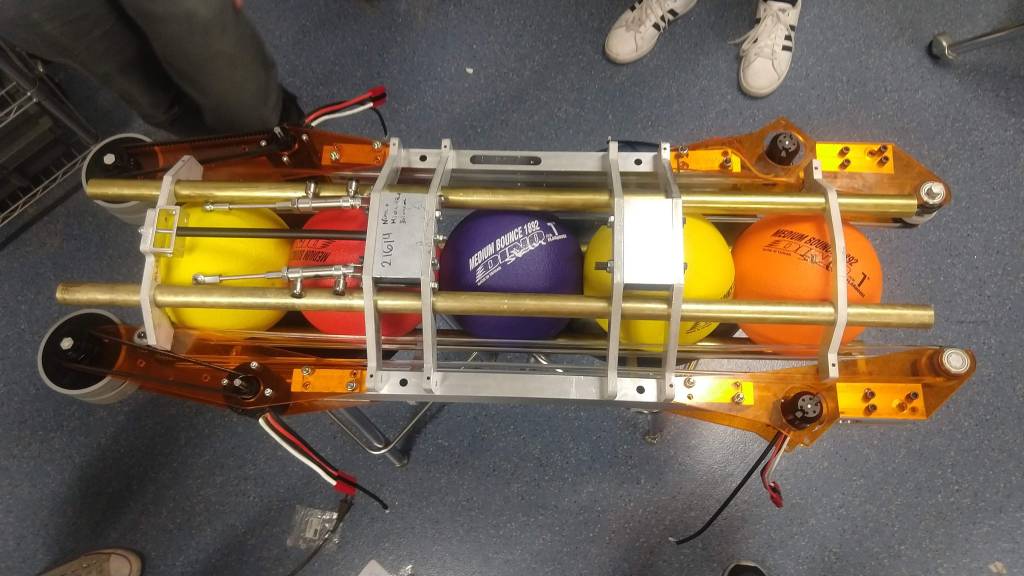

The intake was also attached onto the robot and pistons added to it as well. We have not wired or tested the intake and need to do so as soon as possible as the geometry might need some adjusting as well. However, if all goes well, the only things we will have left to do for the intake and tube will be switching the lexan plates for metal.

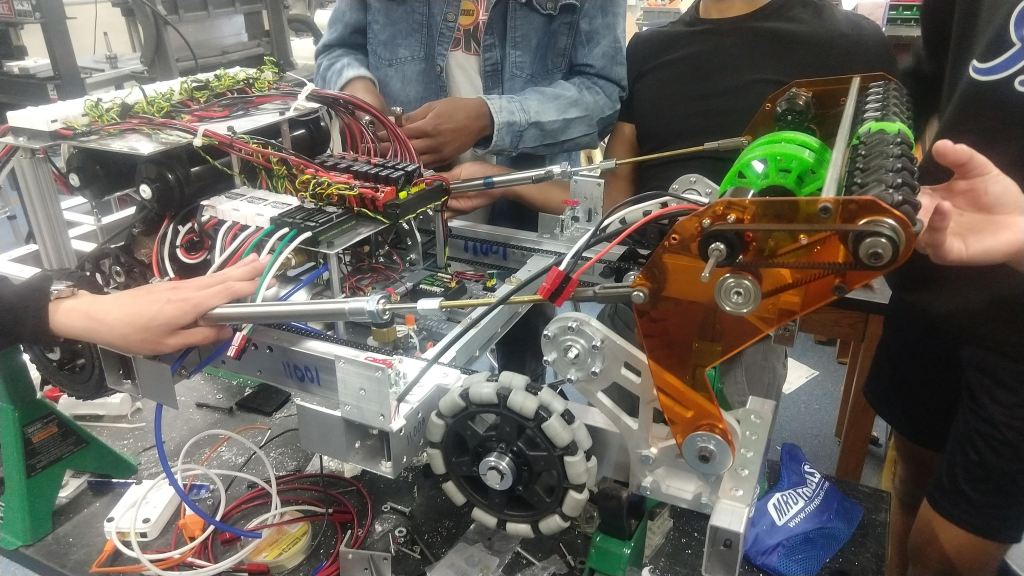

Electrical also had a lot of progress the last couple of days. The electrical board was finished and mounted to the robot (as you can see above). As soon as we attach the tube (which should hopefully be tomorrow) we will get the intake and tube wired (total of 7 motors) and hand off to software for testing. If need be we might also have to add some weights to simulate the weight of the climber (for software to test with the right weight) but it shouldn’t be a big problem.

On a slight side not we got our hooks for the climb from waterjet and they look really cool. We hope to assemble these onto the climber as soon as possible.

More videos and photos to come as we finish up the robot and software starts to test. At this point they have the code finished for the robot but still need to test out ball and tape tracking as well as run pathweaver paths to test out autonomous options. For now I’ll leave you with this funny video.