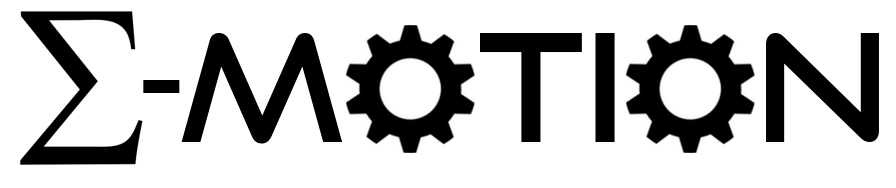

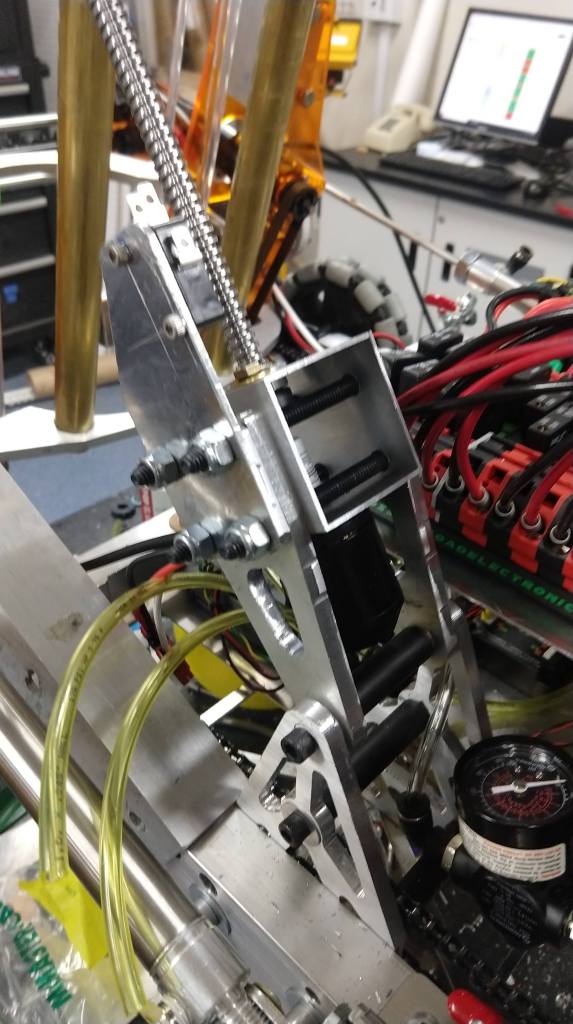

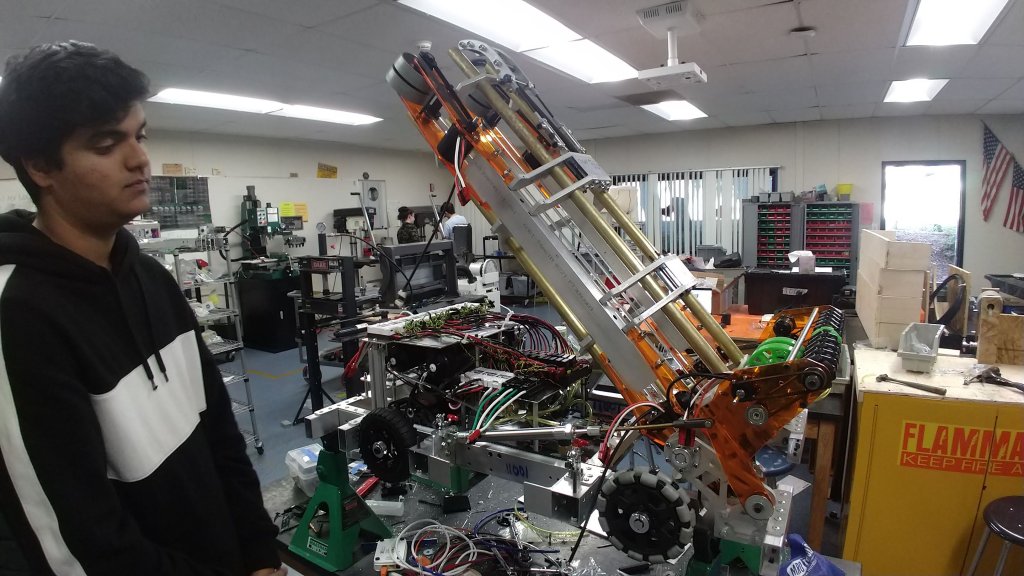

We’re almost done. Today we were able to finally finish up the assembly of the tube and intake as well as get started on some part of the climber (in addition to what is already done). The tube adjustment mechanism was put together and then threaded through the nut on the tube. This will allow us to adjust the tube up and down for shooting balls into the lower and upper port.

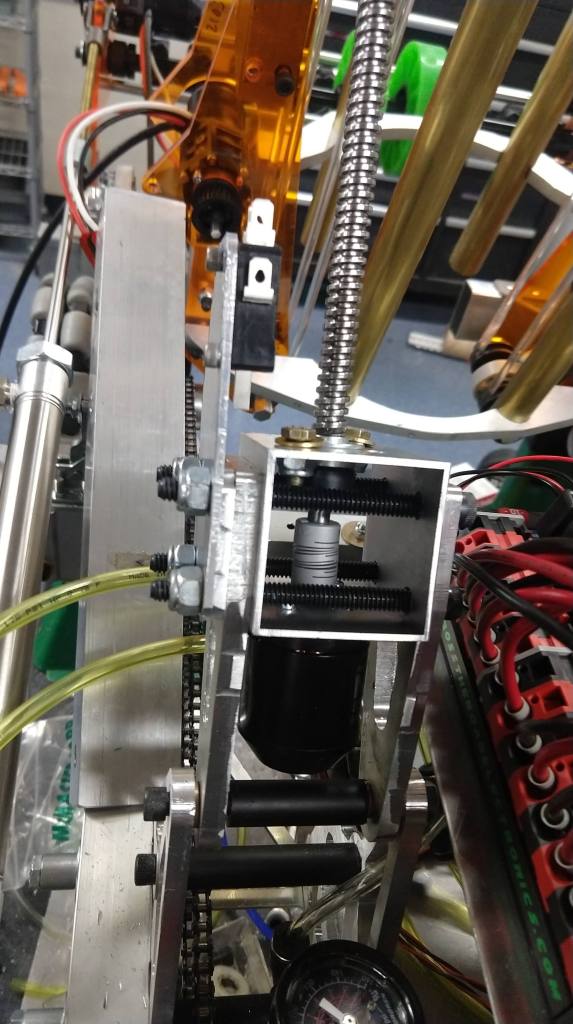

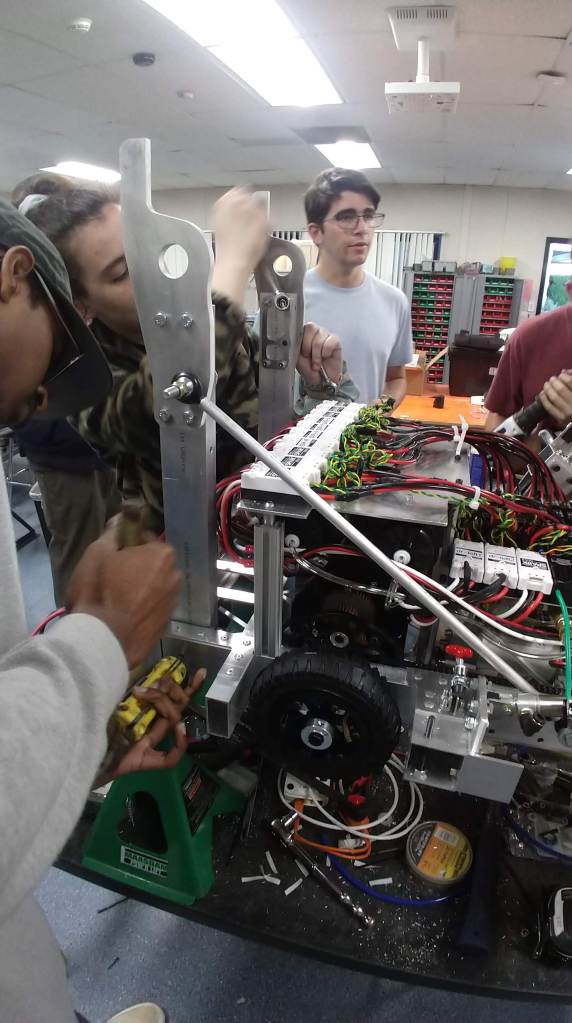

The shafts for the tube were also put in place today. This will allow the whole pivot to pivot near the intake side of the robot. The range of motion so far looks good and just as planned in the CAD. We might however have some slight problems with the tube going down and hitting the electrical plate but those will be resolved quickly if necessary. We also had some problems finding a belt and pulley that we thought had been ordered and received. We will keep looking but for now the tube will have to run the balls from one side (it will work for one ball and hence testing, but if we try to put multiple in they will jam).

We were also able to attach the back tubing that holds up the climber. At this point once the tube and intake are wired (which will hopefully be within the first hour of tomorrow’s meeting) we will hand it off to software to start testing. Climber weight will be simulated and in the meantime we will begin assembling both stages of the climb. One piece is holding us back but that should be done by Monday. In the meantime we hope to at least assemble the whole climber and, if we figure out a way, maybe even try to make that piece in house. This way, software will have a minimum of five hours tomorrow to work on autonomous modes and to iron out controls for the robot while build finishes up the final mechanism. Once it is done, assembly should be a simple shaft and collar onto the robot (and wiring of course). Our hopes are that – excluding the piece we are waiting on – the elevator is finished tomorrow. Software wise, we hope the controls work and that we can have at least one successful autonomous mode of 3 balls in the top port.

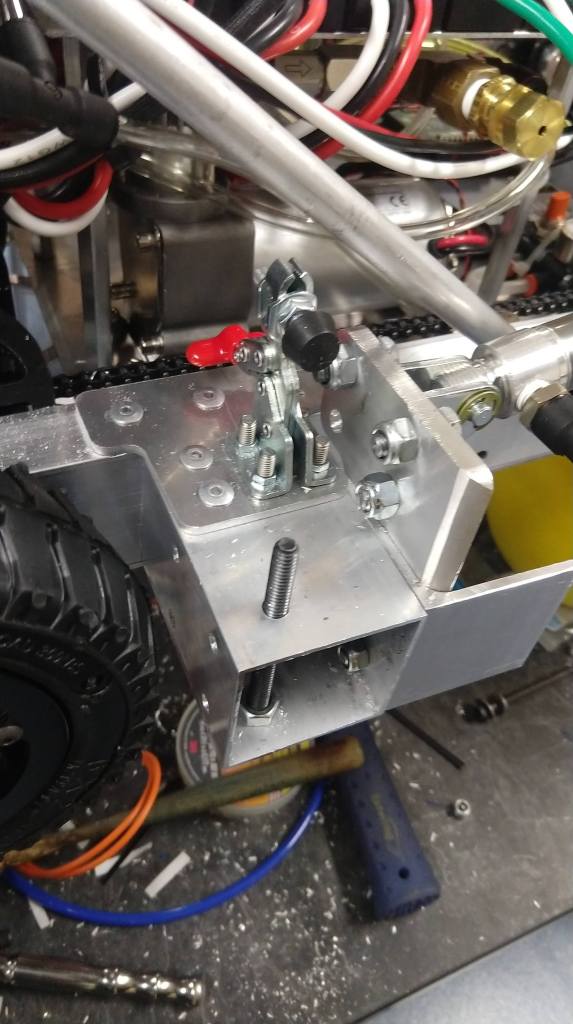

In addition I just wanted to point out something that I forgot to on a previous blog post but just noticed again today. In the past we’ve had problems with bumper attachment and the time it takes to switch bumpers. This year we’ve gotten some new clamps that should be easy and quick to operate as well as sturdy and durable. This will make our bumper switch time drastically lower as well as ensure that the bumpers stay secure. These can be adjusted as well so that the clamping force is lesser or greater (will have to be tested with the bumpers).