We finally got something to work! Most of today was devoted to testing software and the various functions of the robot. After the firmware was updated for the motor controllers (which took a good amount of time), we were able to use the joystick controls to troubleshoot various electrical and mechanical problems. We first started with testing the drivetrain and although we initially had some electrical problems with one side, they were quickly resolved and the drivetrain worked normally from there on. We also checked and the reverse button works as well. This way there is a toggle to reverse the forward direction for the driver. It should make it easier for the driver to grab balls and shoot since the intake and shooter are on opposite sides of the robot.

We continued to test with the tube belts, shooter wheels, and intake. Although some hiccups arose at first (like reversed directions and wrong speeds), we were quickly able to get those things adjusted and have the intake, tube belts, and shooter wheels work just fine. We were not however able to work with the tube adjustment mechanism because of a mechanical issue. Currently the motor for the tube adjustment isn’t transferring torque to the screw and so the actual screw isn’t being turned. A simple tightening of the collar tomorrow morning should fix the problem.

That just about sums up the electrical components so far, but the pneumatic components were a different story. We initially had some problems with leakage from the system and couldn’t get the pressure to build all the way. However, once that problem was fixed, the buttons that were supposed to activate the pistons (both for the intake and for the hook on the tube) did not work. Software should work on a fix and the problem will be resolved tomorrow.

In addition to just testing the robot some mechanical work was done as well. Bumper fabric was put on and brackets for attachment and reinforcement will be put on tomorrow morning. We were also able to miraculously find the missing belt and pulley for one side of the tube and all the videos above were of both sides being run. We also were able to CNC the piece that should act as a rest for the ball in between the intake and tube. The piece should supposedly remove the gap and dead zone we had yesterday. However, as we were putting on the piece we noticed that the bottom of the tube hits it at some angles. We should be able to dremel out small pieces tomorrow for the tube to pass while still keeping the main part there for the ball to have constant contact.

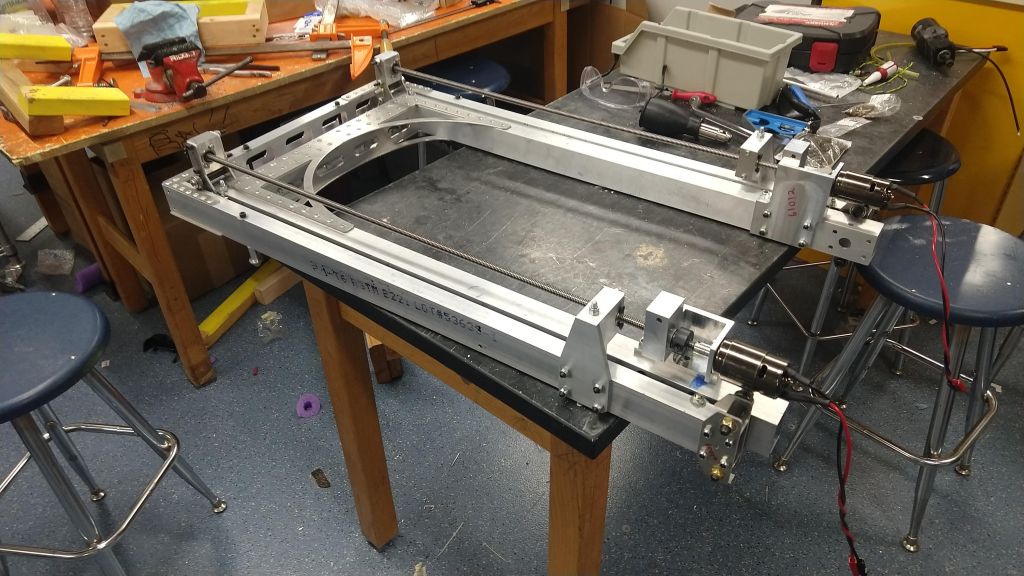

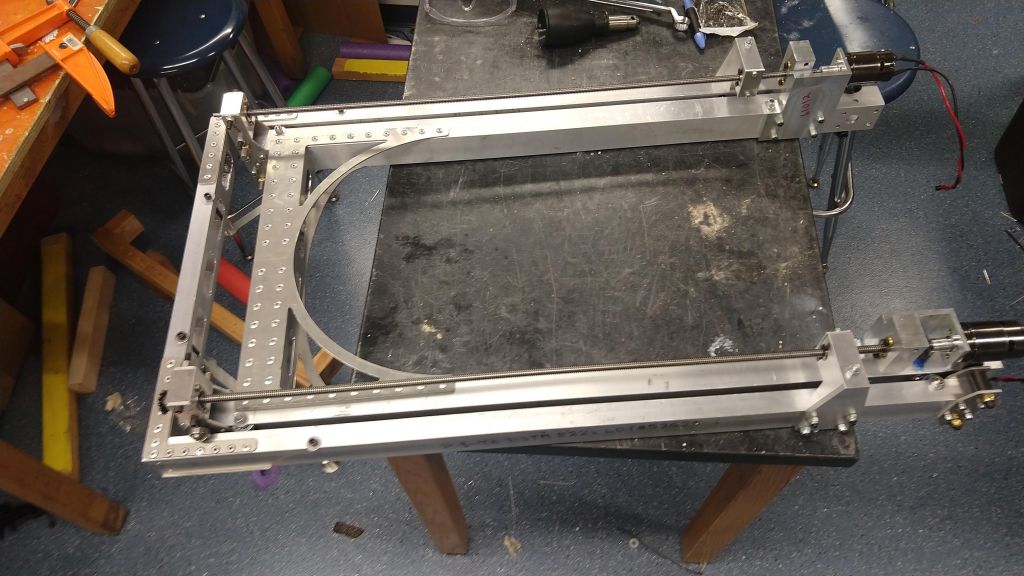

Despite all this, main project off the robot was the climb. We were planning on finishing the whole assembly today and getting the final pieces we needed for completion tomorrow. The assembly was finished with the small exception of the hooks (which will be added first thing tomorrow morning) and the two small pieces we were waiting for to come in on Monday. Not only will the full assembly of the climb be complete tomorrow but we will also be attaching and wiring it onto the robot. Once this is done, software will continue testing mechanisms and working on autonomous.

Overall, today was a success as most of the mechanisms worked without a hitch (after some adjustments). I’ll end the blog by leaving a nice video of us shooting out all five balls.