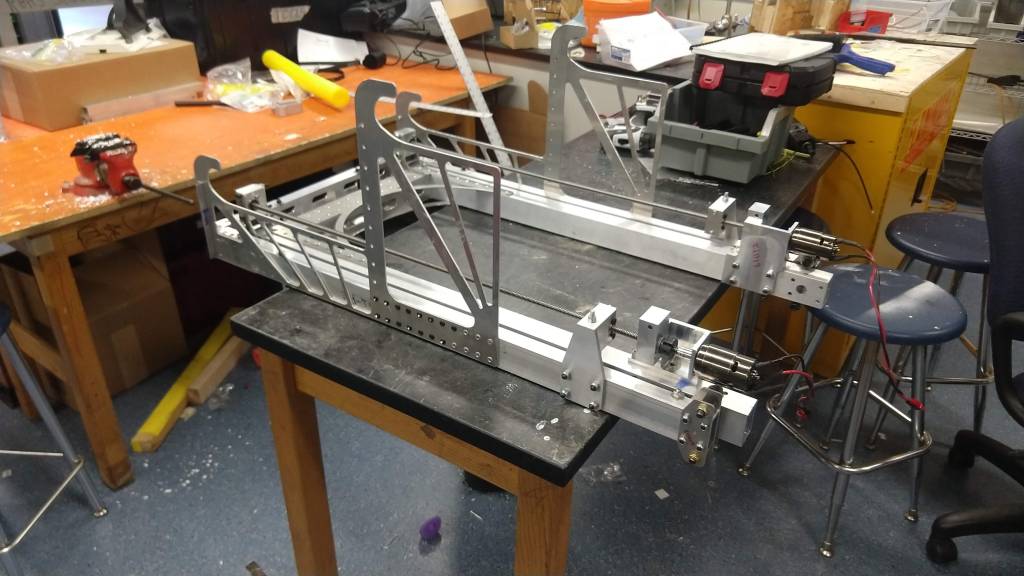

Lots of testing, some problems, lots of good things. We spent the first third of the day today mechanically getting things up to date. The hook stopper for the balls on the end of the tube was moved back. Yesterday we had the problem that the front-most ball was getting burned because the pulleys were touching it. Now, with the hooks back, they work as intended and the balls stay just fine.

We were also able to attach the bottom plate that should have fixed the dead zone and ball jamming problem we had before. Although there doesn’t seem to be a dead zone anymore (which is good – the plate did its job), we occasionally have the ball jamming problem. However, because of the controls, we are able to stop the intake and only run the tube belts, which quickly releases the jam. We’re working out ways to make it seamless.

We also attached bracket to the bumpers and tested them out on the robot. Some small adjustment may need to be done but the brackets seem to be doing their job for now.

Finally, the climber had to be delayed as we still haven’t received the parts we were waiting for. We did, however, attach the hooks onto the climber and all that is left should be the blocks we are waiting for. Those will be machined tomorrow and, because there is a lot of software testing to be done, we’ll probably attach the climber at the end tomorrow and start testing it on Wednesday.

After all that was done, we continued testing the robot, getting pneumatics to work, and driving at the end. Overall, everything worked out well. We got the pneumatics to work fine with the controls and the reverse feature (letting the driver switch which side is forward on the robot) was added to the driver controls.

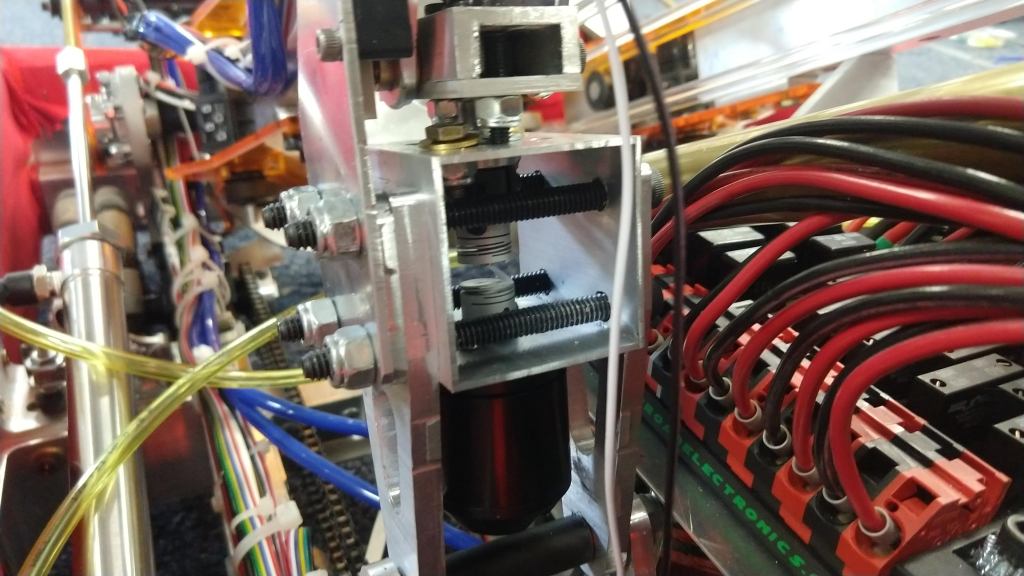

There was, however, one exception to the flawlessness of the initial tests. At first, the tube adjustment that had a mechanical problem yesterday worked perfectly. Mechanically we fixed it in the morning so all the torque was transferred from the motor to the screw. But, for some reason, the motor stopped turning at one point. Then, once the code was reverted back, the tube adjustment was tested and the collar connecting the motor and shaft quickly snapped. A new one should arrive tomorrow and we’ll continue testing but for now the adjustment remains out of service.

Despite the adjustment problem, we moved the robot to the field and tested. Today we put on a long roll of carpet that we hoped would improve the carpet situation. We are currently having some problems with it staying down and not being moved by the robot but we’ll work on resolving those quickly.

On the field we tested different things like whether the robot could shoot into the top port when pressed up against the port. We could get 3-4 balls in but never got in all 5. Once we have the tube adjustment working we’ll get the right values so that the tube position for that shot is a macro and we can easily do it every time.

We also wanted to see whether the color wheel could be spun by the shooter wheels. Although we were able to spin it, the line-up was not the easiest and we would have to be very careful. In addition, the wood made a slight cut into the shooter wheel, which is definitely not ideal. We’ll keep working to figure out what the best way is to accomplish the task.

Finally, we just spent some time grabbing balls and shooting them into the low port (because we didn’t want to spend the time to move the tube screw manually). This is definitely not representative of the speed we want or will be running at competition, but is definitely a good representation of how we might do things.

Overall, things are going pretty well. Some problems – like the tube belts sometimes coming off and the balls sometimes jamming between the intake and tube – still need to be addressed, but the overall picture checks out and things are looking good for this robot.