Sorry for not writing the last couple of days. There hasn’t been much in terms of measurable progress because we have been doing a lot of testing and driving and we did not meet on Wednesday.

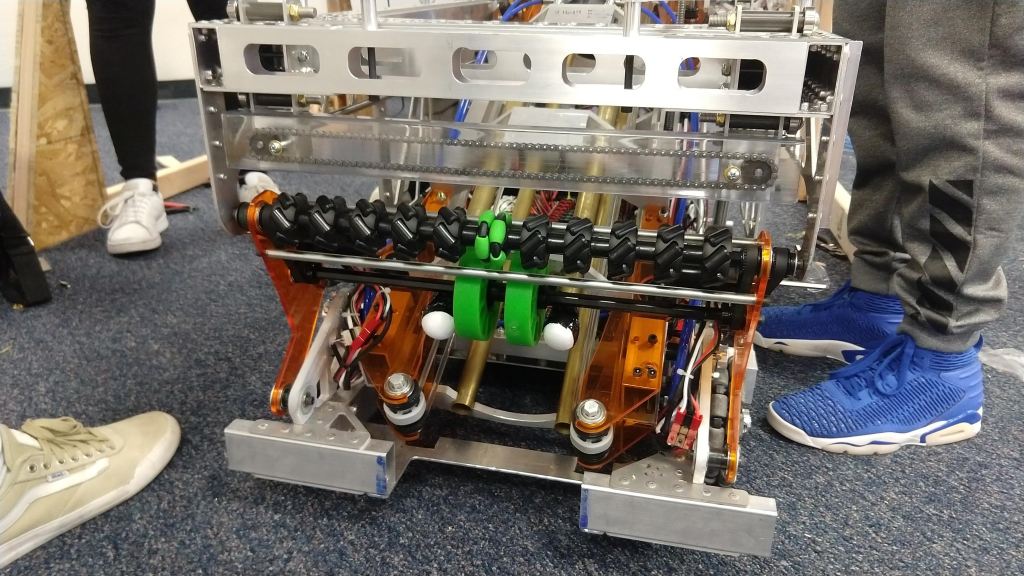

Anyway, the entire climber mechanism was prepared on Tuesday (February 18th), while at the same time a new shaft coupler was added for the tube adjustment and we finally got that to work. Software spent some time testing autonomous and limelight drivetrain adjustment – where the drivetrain should be able to automatically adjust to the center of the top port – as well. The values for the adjustment should be almost tuned, which means that for now the drivetrain should be able to adjust automatically to the port. We’ll keep testing tomorrow and hopefully send out a video of that as well. Initially we did have some problems with shooting all five balls consistently (as you can see in the video below) but those were fixed with a slight delay on the pneumatic hook holding the balls back. This gives the shooter wheels enough time to get up to speed.

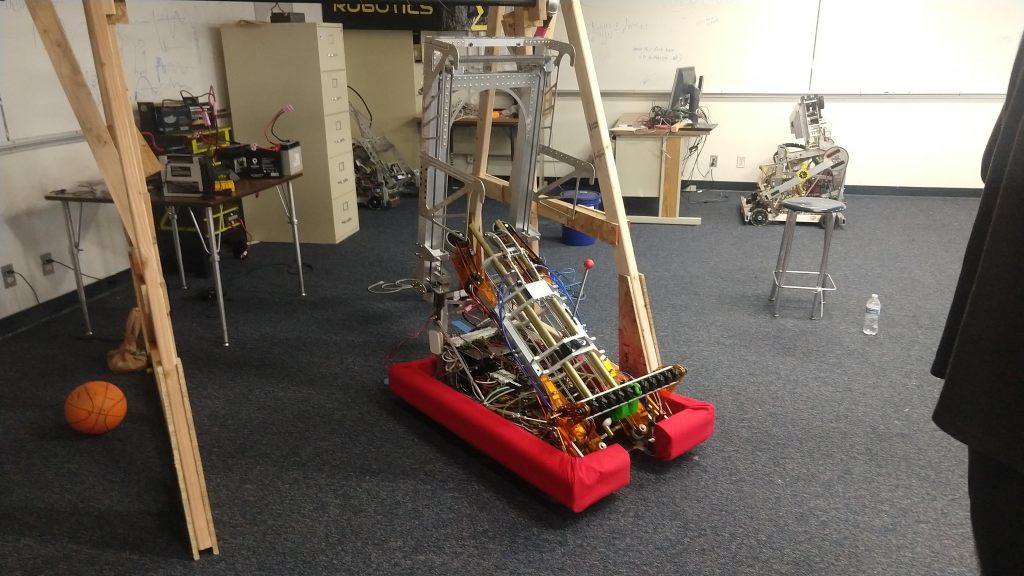

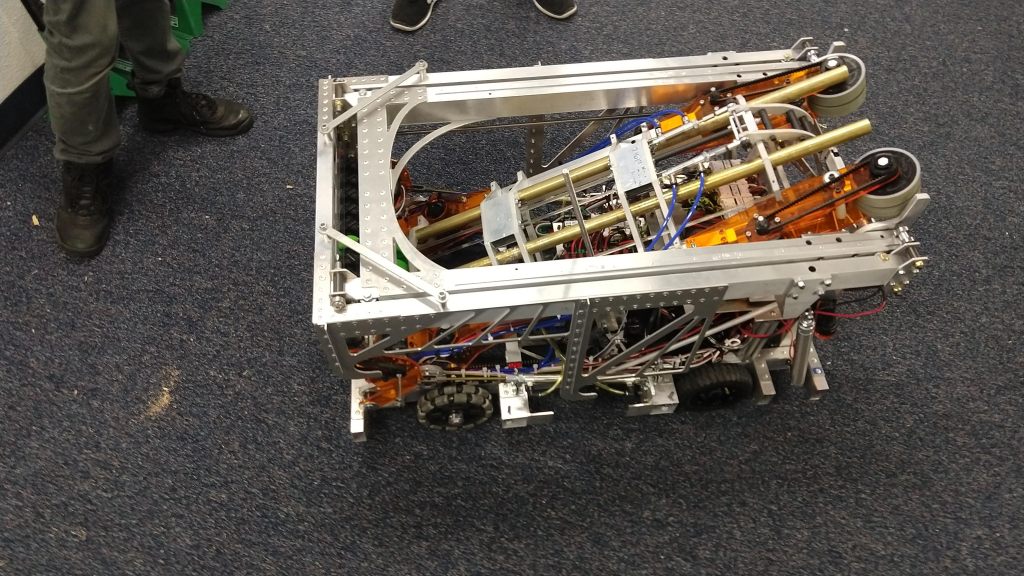

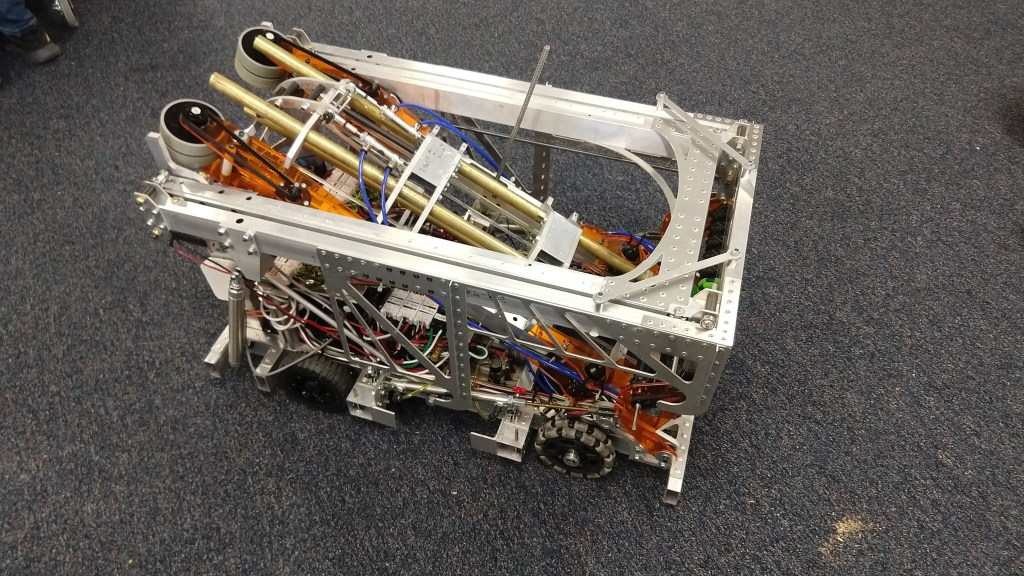

After we did some testing out on the field we started putting on the fully assembled climber mechanism. It was attached to a certain extent on Tuesday and its full assembly was continued and finished on Thursday.

On Thursday the elevator and its pistons were fully attached. We were able to weigh the robot but, since there was nobody from software at the meeting, we were unable to test the climber. Nevertheless, we got some driving in and tested some long shots. For our purposes, the speed and distance of the balls shot seemed enough. We want to be able to shoot from at least the edge of the trench and we should be able to do just that.

We also weighed “Baguette” (still the unofficial name) and we seem to be in the clear for now.

We were also able to put the robot on the climb bar using the hooks but not powering the motors (because we didn’t have software there). We initially tested it out on the level bar and that worked out perfectly. The robot doesn’t swing out much and if the motors are able to lift it, we should be able to have a quick and efficient climb.

We also put the robot on the slanted bar (which is highly unlikely to happen in a real match) and only then did we run into some problems. It slipped a little, but that should be easily fixed with some rubber or some other material that’ll give it some more grip.

Towards the end of the meeting our tube adjustment mechanism’s shaft coupler broke . . . for the second time now. We’ve bought new shaft couplers and some that aren’t flexible (as were the two previous ones) and we hope they will resolve the problem. In any case, because of the fast McMaster shipping, the couplers arrived this morning and we quickly replaced the broken one. At this point the replacement time is less than 10 minutes so we could – if needed – easily replace one in between matches at competition.

Once the coupler was replaced, we spent basically all of today trying to get the climber to work. After a lot of initial software problems with motor controllers and code not working, we were finally able to get all the controls ready to test. Initially, just running the motors on their own, things seemed to work out fine.

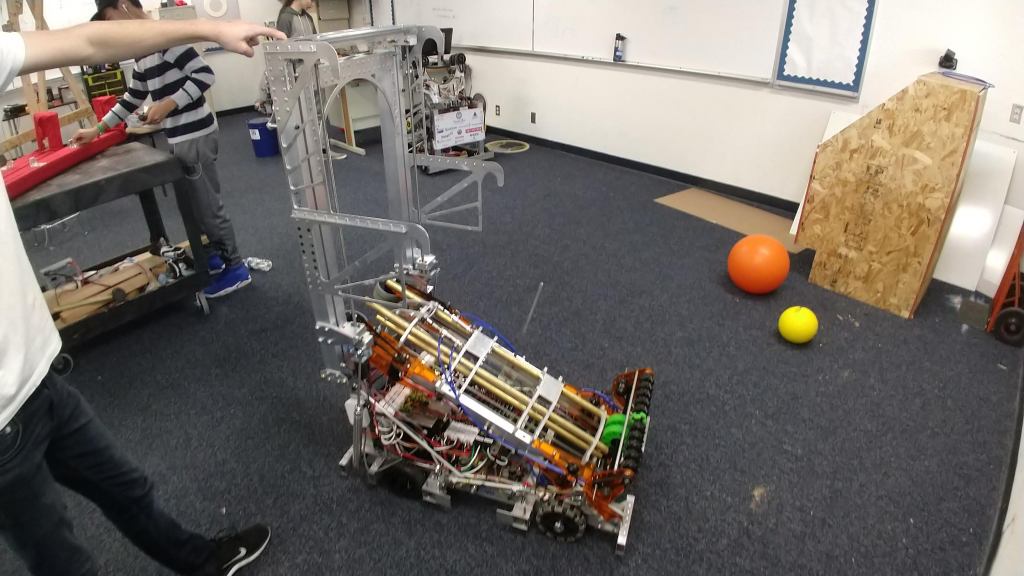

Then, we tested it on the bar and the problems came rushing. At first (as you can see in the video below) the climber would basically just stop once it started actually lifting the robot. Controls-wise, the joystick on the controller was being pressed fully down and yet it still didn’t work.

Then, we brought up the speed on the climber to 97.5% and tried slamming it down quickly instead of steadily moving the climber down and adding power. This seemed to work better, but it still wasn’t close enough.

Finally we gave it one more try with the bottom hooks instead of the top ones. For some reason this actually worked even though it shouldn’t have made a difference.

We kept on testing various scenarios and possible variations but all to no avail. So far we seem to think that it is a problem either with the motors themselves or with the motors not getting the right power. Nevertheless, some mechanical solutions are also being devised so the motors don’t have to work as hard. We’ll continue testing the climber more tomorrow and hope for a miracle in the meantime. There should also be a lot of time for software to work on autonomous so we’ll see how that goes as well.

So far, overall, lots of good things happening as well as some kinks to be worked out. If we are able to get a solid autonomous routine and limelight adjustment going as well as some good driver practice in before the Del Mar Regional, we should be in good shape.