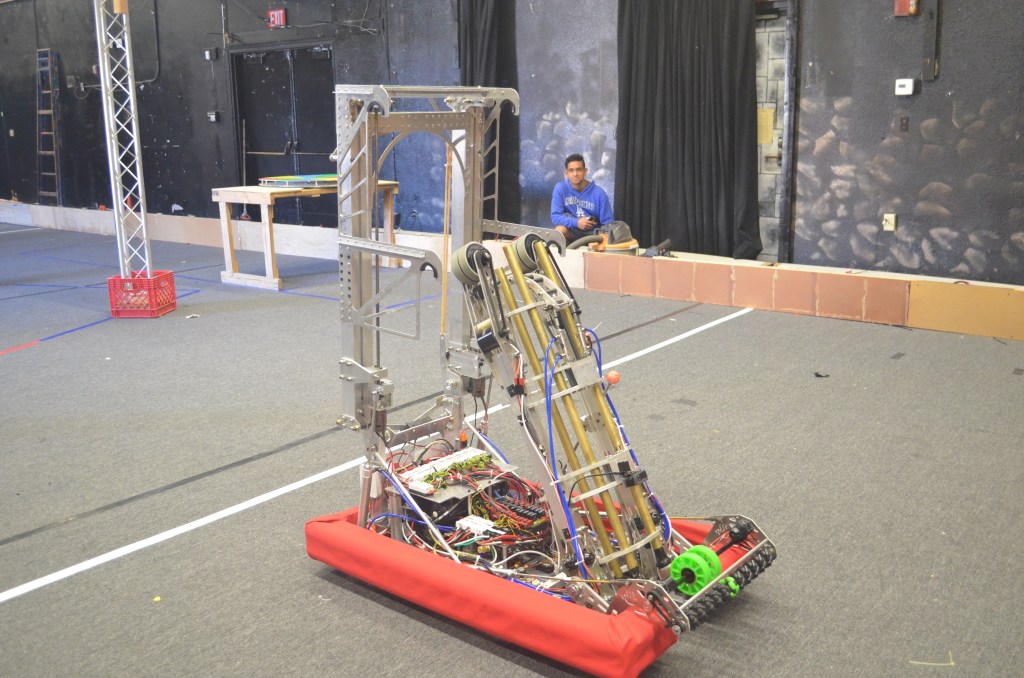

Sorry for not posting for a couple of days. After the full systems check last Wednesday we spent Thursday and Friday giving software some time to work on their necessary tasks. On Thursday, we were able to attach the bottom limit switch for the tube adjustment mechanism and get it to work. This means that now the tube can be brought all the way to the bottom without the possibility of a mechanical failure due to slamming into the hardstop too hard. This is a first for the team (we haven’t really worked much with limit switches before) and it will definitely make controlling the robot infinitely easier.

On Friday we put a constant force spring on the climber that should have helped us climb faster and more efficiently. However, once we started testing we found that the elevator was unable to lift up and consistently tripped the breaker. At the same time, software tested a couple of smaller things while drive team started practicing a little bit. We were able to temporarily set positions manually by having the operator read the encoder values off of the smart dashboard and use the joystick to move the tube to the right position. We also encountered problems with pneumatic leaks that persisted into Saturday.

On Saturday, we decided to go over to 3647 (Millenium Falcons at Torrey Pines High School) and practice on their full field. As we started driving around and shooting balls, the pneumatic problems became ever more prevalent. It turns out that some connections were simply not sturdy enough and they would pop every once in a while (making a very loud and concerning sound in the process). Nevertheless, Krish and Matt were able to replace those bad connections (along with another one today) and it seems like the pneumatic system should be stable for the time being.

In terms of driving, we very quickly encountered some problems. Most notably our ball pickup was not fast enough (both due to lack of driver practice and due to some problems with intake speed which were also fixed today). Our line-up for the top port (we spent most of the time trying to shoot from the end of the trench) was decent but definitely needs some work. We line-up in two ways: drivetrain and tube. The tube alignment was definitely off because the bottom limit switch broke quickly after we drove into the color wheel with the tube up. Therefore, the operator had to rely on sketchy and not accurate tactics to get the right angle. The other line-up (drivetrain using limelight) also needs to be tuned. Right now it wiggles back and forth between the center position. We can work with what we have but software should hopefully be able to get it to stop in the middle.

Climber side note: Because of the stress caused on the motors when we tried using the constant force spring, we decided to take it off. We tested the climb again and it worked perfectly. However, in our process of testing the spring, we had a small part of the climber break. New parts came today and we were able to quickly repair it (and in the process make sure it doesn’t break next time) so that the climber works. Therefore, we were not able to test out our climb on the swinging scale at 3647’s field. Nevertheless, we will have time during Friday’s practice matches to tune that.

With the practice on the real field behind us, we were able to use the lessons learned there and fix many problems today. Software got position macros to work so that our tube adjustment should be accurate every single time. Tomorrow they will finish coding a simple autonomous mode (more complicated paths will continue to be worked on while drivers practice) and tuning drivetrain limelight alignment to stop in the middle.

We also got the other set of bumpers done today and bumpers painted on as well. Things overall are looking well. Our fully coded robot should be done tomorrow so that Wednesday is all drive time with some additional drive time and prep on Thursday before we set up. This weekend is our first competition and with all the features and functions of the robot (paired with a great pit crew and drive team) we hope to perform much better than last year and have twice the fun in the process.