It’s been a while since I’ve written a blog. But, that doesn’t mean our time has been devoid of progress. We started our weekly Wednesday meetings and have been doing some training for teams that can do it virtually. Simultaneously, we’ve been working on both improving Torpedo (our 2020 robot) and developing the design for our potential 2021 robot.

One notable event in our team training was our recent participation in Chezy CAD, the CAD competition hosted by FRC team 254. Fortunately, we had enough people interested in participating that we were able to fill two teams up and design two unique robots over the 2-day event. The challenge was to design a mechanism to climb up a vertical pole. Overall, it was a great learning experience for everyone involved and hopefully we can get even more people to join in next time.

But, while new members have been training diligently (and hopefully learning a lot :)), we’ve had some of our older members working on improving Torpedo and making it as good as it can get. When looking back at this year’s matches, our shooting stands out as sloppy. We simply were not able to consistently get shots into the port. The biggest source of the problem becomes a little bit clearer once you look at exactly where the balls go. In an average shot of five balls from the trench, we would often have balls undershoot, overshoot, and fall right in the middle of the port. This occurred even when the tube angle and drivetrain position stayed perfectly motionless throughout the shot. So, there was a clear problem with output velocity. Under closer examination, we were not running our shooter wheels through a PID control loop and they were easily varied by things like battery charge and general inconsistency. So, we set out to implement PID on those wheels.

However, when implemented, the maximum output speed lowers and Torpedo can no longer shoot from the trench. After some more examination, we found the ratio on the shooter wheels to be 2:1 (ie: the wheels were running at half the speed of the motors). So, we switched out the ratio of the wheels to a 1:1 in order to allow our software to implement PID control and ensure a consistent output velocity.

Upon a second glance, this actually improves our shooting in a couple other ways. To start, increasing the speed of the wheels makes it so that the variance within input speeds into the wheels (via the belt) doesn’t have as big an impact since the increase in speed through the wheels will be considerably larger than the variance in tube velocities (which heavily rely on loose friction). Additionally, having a faster output speed makes our shot a bit straighter, which will allow us (with proper tuning) to have a lot more accurate shots that hopefully consistently reach the inner port.

As you can see, even with PID not implemented (it was done right after shooting that video), we have some more consistent shots that go roughly to the same spot. This will hopefully only get more accurate. Finally, the main problem we are now having is that balls consistently bounce out after being shot in. Once we get some really accurate shooting going with PID, we’ll be able to aim our balls so as to hit the angled piece of the port and go directly down (or go for the inner port).

We will continue improving the shooting and start to adjust and tune our limelight adjustment over the next three weeks so as to hopefully have an almost fully autonomous shooting sequence by the time we get to winter break.

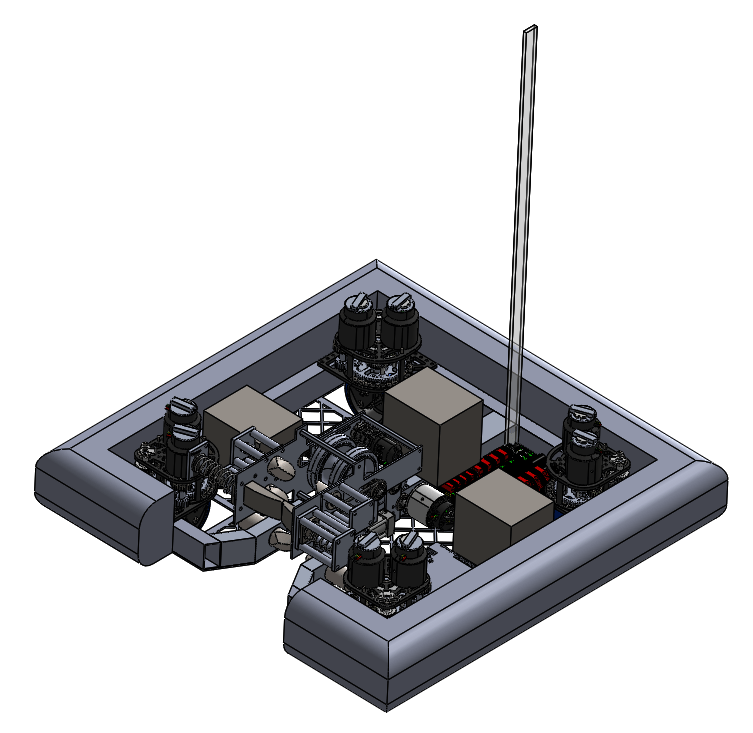

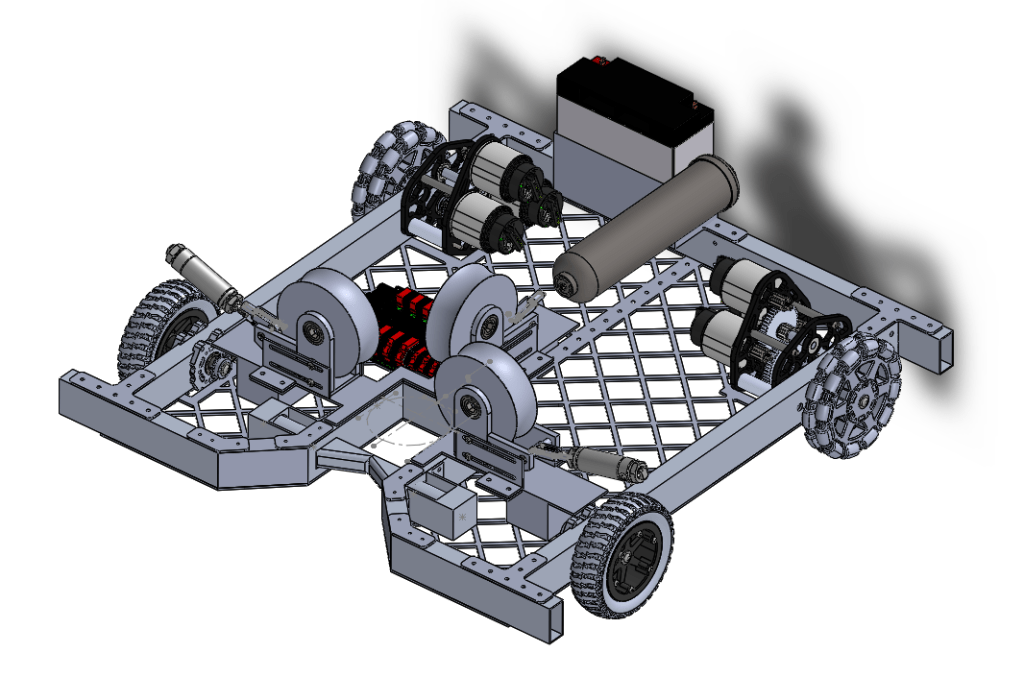

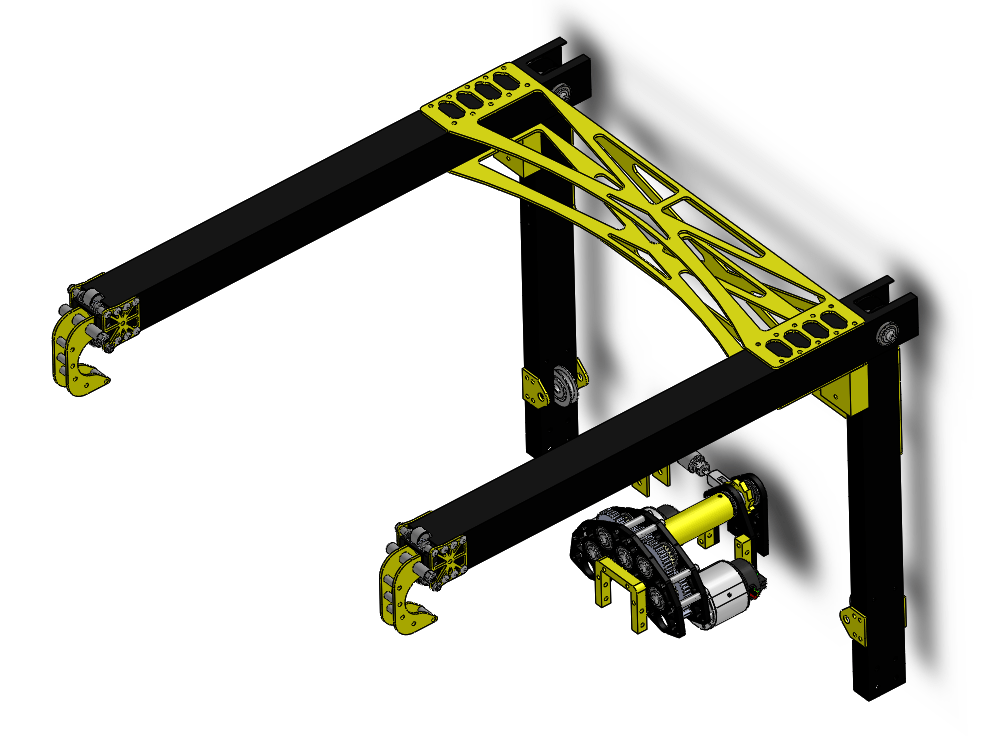

As we prepare for the 2021 season, we have also been working on a design for the 2021 robot. This new design is almost a complete architectural rebuild of Torpedo, but addresses all of the key issues and fundamental flaws in the overarching design of Torpedo that were mentioned here.

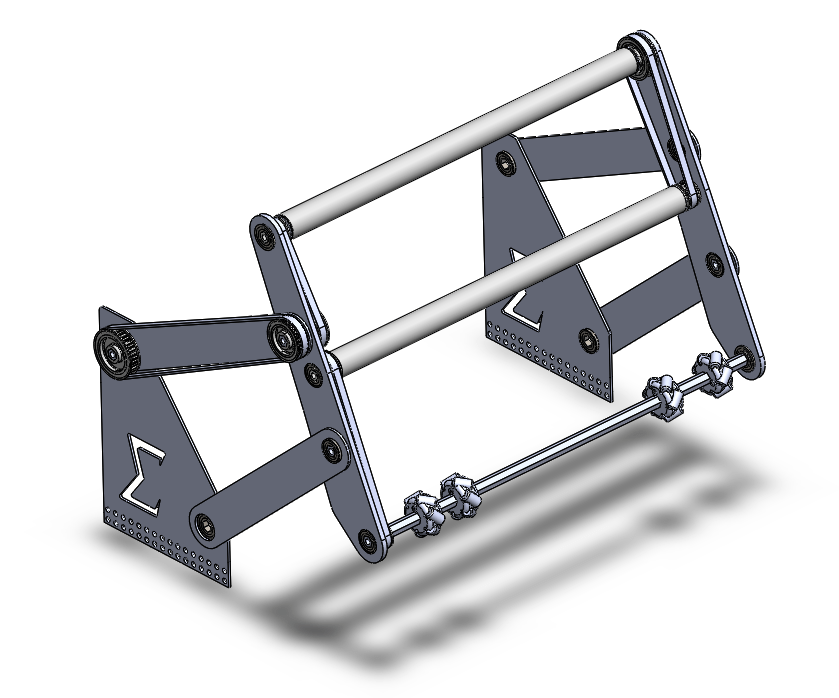

Most notably, the intake has had a great deal of progress and has taken some shape and form. Some immense design challenges were associated with it that were elegantly addressed and we will soon have a wonderful machine that should shoot balls into our robot faster that we shoot them out (that’s just some imagery I’m obviously joking).

Additionally, a thorough design review was performed on the climber and drivetrain and some key areas for improvement were noted. In order to reduce part count and improve manufacturability of the climber, some areas where bearings and complicated parts were used were swapped for Ultra High Molecular Weight Polyethylene and aluminum plates, which makes our elevator a lot easier to build and maintain. Most of these changes are internal and not visible on the outside.

I have to, of course, mention the crazy coloring. In part this was just playing around in the program, but it was also a vision for the future. Many teams color their robots and with potentially some time saved on the design process, we might be able to spare a couple extra days to get our parts powder coated by a potential sponsor if we decide to build this robot. This is something that we need to thoroughly research and plan if we decide to do it, but for now, it’s just some eye candy.

Finally, the final new development in our robot design process was the testing of our shooter prototype. We hooked up the two motors on the hooded shooter to the intake wires on our 2019 robot (Flipper) and tested various shots on the field, noting the hood angle successful at each position.

As you can see, this is wildly inconsistent. There are many variables that cause this, including variance in input speed (placing the balls into the shooter), slightly tilts in the holding of the prototype, a flimsy architecture janky structure, inconsistent rpm on the wheels, and plenty more. But, after averaging out our results from several tests, we were able to find a rough range of values that give us a range of hood positions and angles for our design. We will continue to test different variations on compression, speed, angle, and hopefully even test a rocker wheel at the top for precise backspin. A future prototype will also hopefully be attached to a “tower” prototype that provides consistent feed rates and more accurate results.

As we go on into the final stretch of 2020, we will continue to train new members and get everyone ready for the season, improve Torpedo until we cannot anymore, and diligently prepare the robot design and entire team for the 2021 season and all the exciting adventures that are sure to come with it. Lots of planning to do, work to come, and fun to have ahead. And now, I leave you with Torpedo just chilling in his room.

✌️