As we finish up the final couple weeks of school, we’re also looking to preparing the team as much as possible for the season to come. Since the last update, we have some more progress both on Torpedo and on the new robot (we should start thinking of names for it).

Some of the fundamental software changes needed since March have finally been implemented and are working their “magic”. We tuned PID on Torpedo’s shooter wheels and were able to achieve some considerably more accurate shots that provided a glimpse of the full potential of this robot. This was mostly tested with auto line shots — which generally tend to be easier to consistently get in — but some trench shots showed some of the downfalls.

It may be difficult to notice in the video, but when looking at it in-person and specifically tracking where the balls are hitting each time, the spread is considerably lower than before.

With ball consistency now handled, we can move on to addressing accuracy each time. This will be done by using the Limelight vision system to track the target and rotate the drivetrain and tube angle to accurately shoot the balls. Right now we rely on human side-to-side alignment and pre-set positions for angles of the tube for various placements on the field. Although this works well, it yields some error and, more importantly, is quite slow.

While it may be difficult to notice, all the balls in this video actually entered the top port. But, because of the angle and speed at which they entered, we rarely are able to get all 5 in from the trench and most of the time at least one ball bounces out. This can be avoided by properly using vision systems to adjust our shot and shoot the balls with the same velocity in the right part of the port, or with a different velocity and a different part of the port. In any case, precision of this kind cannot be done by the drivers. Hopefully we will be able to get these automated system running and tuned by the time the season starts.

Simultaneously, our drive team has been able to have more practice with Torpedo and the progress is definitely noticeable. Driving has gotten a lot smoother and cycles keep getting faster and faster. Moving the climbing bar outside has allowed us to integrate climbing into the driver practice sessions and that has led to an improvement in climbing speed and consistency from the last drive team.

That video shows the first step to a much faster climbing execution that should be very useful for competition or the skills challenge. But, overall, great improvements in the driving make the robot better each day. Hopefully once those fundamental software improvements are implemented, our drivers can get even more time to perfect their form.

By constantly improving and perfecting Torpedo, we are not only learning more and pushing its capabilities, but we are also setting up a backup plan of sorts. Because of the pandemic, it is uncertain how often, for how long, and when we will be able to meet to build a new robot. Therefore, incrementally improving the software and driving of Torpedo also prepares us for the worst to come in 2021 in addition to teaching us some great lessons about engineering.

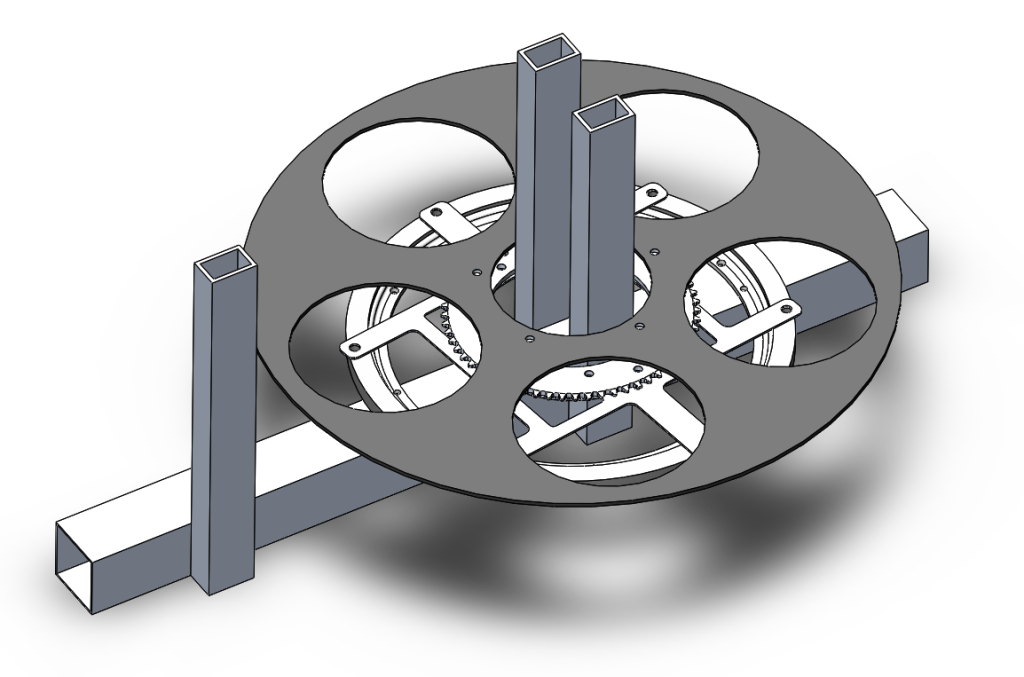

There has also been some progress with the new robot as it slowly comes together. We’ve been doing incremental design reviews on the new changes being made and are able to start focusing on some smaller stuff for the climber, drivetrain, and intake. We’ve also had the initial structures and framework of the spindexer completed and the transition to the shooter is on its way as well.

Within the next month these developments will all come together and we will hopefully begin making detailed drawings for parts to be made. The goal is to be completely done with the robot by the end of 2020 and we seem to be right on track to get there.

Finally, I have one small note. We made a new “exhibition” of sorts in the build room by displaying our 2019 intake iterations on the wall. This highlights the 7 different iterations of the intake plate that we tested and went through (there might be more but this is all I could find). It’s a cool visual but also shows the importance of iterative improvement. Our intake was not great in the beginning and was barely doing its job at our first regional. But, by persisting and making it better and better (even completely changing our hatch mechanism for the second regional), we were able to iteratively find a systematic solution to the problem. This is a cool visual, but there is meaning behind it and the iterative and systematic thinking portrayed in this display should continue to be embraced by the team. Enjoy. 😁

You can see all the photos and videos from the off-season here.

✌